Fire resistant rope is typically made from high-performance synthetic fibers such as para-aramid (e.g., Kevlar®, Technora®), meta-aramid (e.g., Nomex®), PBI (polybenzimidazole), or fiberglass. These materials are engineered to withstand elevated temperatures, resist ignition, and maintain tensile strength under thermal stress.

At Hoater Ropes, our fire-resistant rope lines are specifically designed to meet the needs of industrial, firefighting, military, rescue, and utility applications where heat exposure and flame resistance are operational requirements.

In industrial applications, selecting the right fire-resistant rope involves assessing the material's thermal resistance, mechanical durability, and certification compliance. Fire-resistant ropes used in professional environments must:

Maintain structural integrity at high temperatures

Resist flame propagation and ignition

Withstand mechanical load under thermal stress

Be chemically stable and UV resistant

Thermal Stability: Up to 500°C (932°F) short-term

Key Benefits: High strength-to-weight ratio, flame resistance, low elongation

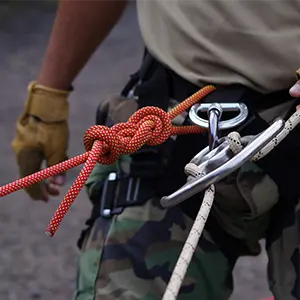

Use Cases: Rope access, aerospace, military rigging, high-heat rescue scenarios

Thermal Stability: Up to 370°C (700°F)

Key Benefits: Flame-resistant with excellent chemical stability

Use Cases: Electrical utility rope, fire-resistant harness systems, rope sheaths

Thermal Stability: Over 700°C (1300°F)

Key Benefits: Exceptional heat resistance, non-melting, non-dripping

Use Cases: Specialized environments such as refineries, steel mills, and fire entry teams

Thermal Stability: Up to 1000°C (1832°F) with coatings

Key Benefits: Excellent insulation, low cost, but lower flexibility and tensile strength

Use Cases: Static insulation wraps, heat shielding, non-load-bearing applications

Note: For dynamic or load-bearing applications, fiberglass ropes are generally not suitable due to brittleness under tensile load.

Industrial fire-resistant ropes are widely used in the following sectors:

| Industry | Application |

Fire & Rescue | Lifelines, rapid descent, fireground operations |

Energy & Utilities | Hot stick ropes, transformer area rigging |

Military & Defense | Helicopter extraction, breaching, tactical rescue |

Oil & Gas | Rigging in refineries, hot pipe maintenance |

Aerospace | Cable control, parachute deployment systems |

Steel & Foundry | Slag pulling, thermal containment ropes |

Our fire-resistant rope products at Hoater Ropes are engineered to perform in these demanding conditions with full traceability and testing documentation available upon request.

When sourcing fire-resistant rope for industrial use, it's essential to evaluate:

Know the continuous and peak temperature resistance of the rope's core and sheath.

Match tensile strength and elongation properties to the specific use case (e.g., static line vs. dynamic descent).

Look for compliance with:

EN 1891 (low-stretch kernmantle ropes for rope access)

NFPA 1983 (Life Safety Rope for Emergency Services)

GB 24543-2009 (China fall protection safety ropes standard)

XF 494-2004 (Chinese fire service fall protection equipment standard)

Ropes exposed to flame or radiant heat should have heat-resistant sheaths woven from aramid or hybrid fibers to preserve surface integrity and prevent abrasion breakdown under load.

Applications in outdoor or corrosive environments require ropes with enhanced chemical and UV stability.

Fire-resistant rope is a specialized product category, critical for environments where heat exposure and fire hazards are part of daily operations. The right rope material—Kevlar®, Technora®, Nomex®, or fiberglass—must be selected based on the thermal, mechanical, and operational requirements of your application.

At Hoater, we combine material science with industrial rope manufacturing expertise to ensure maximum safety, performance, and reliability for our clients. If you're seeking dependable fire-resistant rope for your project or procurement needs, reach out to our technical sales team for tailored consultation.